On July 4,2025, the ‘sixth 2025 Symposium

on innovation in high-reliability electronic manufacturing and microelectronics

assembly process technology’, hosted by the Sichuan Institute of Electronics,

co-organized by the SMT/MPT Professional Committee of Sichuan institute of

Electronics, and supported by institutions such as the Sichuan Institute of New

Electronic Processes and New Materials Application, was grandly held at Crowne

Plaza Chengdu New Hope High-tech Hotel.

At the conference site, staff from the

Marking Department and Sales Department of Purbest warmly received visiting

clients. They gave a detailed introduction to the core advantages of the

company’s products, including Hydro-Vacuum and Vapor SUI. By showing introduction

videos of relevant electronic components, they provided professional technical

support and answers to the clients’ questions, and also shared the rich experience

accumulated by the company in the filed of electronic production equipment.

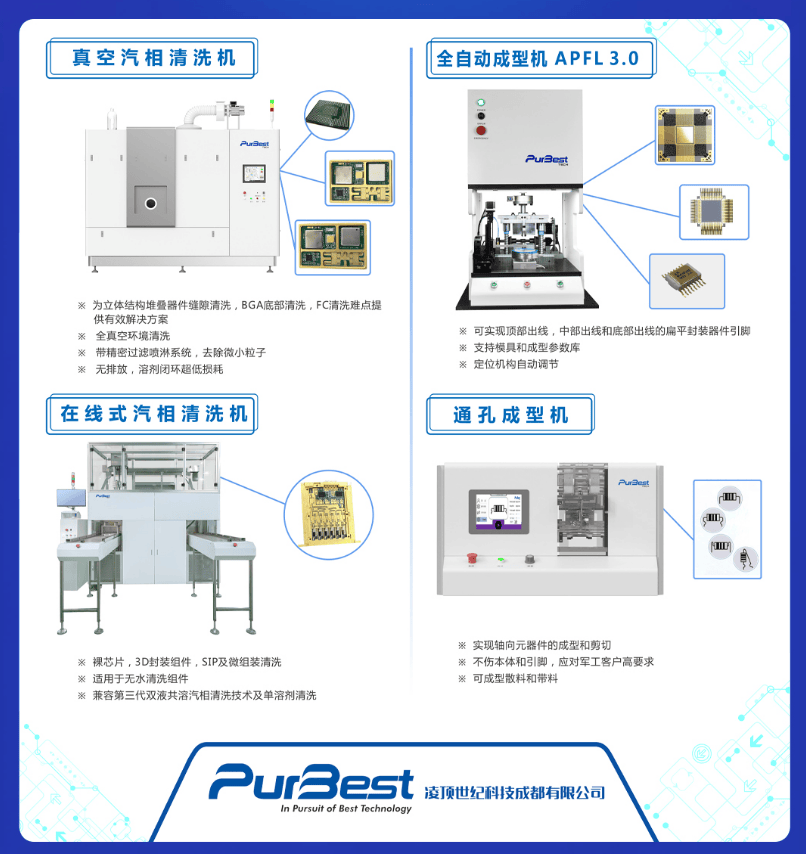

Purbest’s Vacuum Degreasing System can

improve efficiency and quality in scenarios such as gap cleaning of

three-dimensional stacked devices, BGA bottom cleaning, FC bottom cleaning; The

automatic forming machine APFL3.0 can realize pin forming of flat package

devices with top outlet, middle outlet, and bottom outlet, providing an

efficient solution for the industry.

In addition, products such as Vapor SUI

Inline and THTF have also attracted wide attention. They can meet the needs of cleaning

chips ,3D package components , SIP, and the micro-assemblies, and are

compatible with the third-generation dual-liquid co-soluble vapor phase

cleaning technology and single-solvent cleaning, providing strong support for gap

cleaning of three-dimensional stacked devices, BGA, FC cleaning , etc.

Addressing the emerging cleaning process challenges

and pin forming application needs, Purbest has won high recognition from on-site

customers by providing professional cleaning test services and personalizes

custom lead forming services to tailor the best practice solutions for

customers. We provide effective solutions for the emerging cleaning process

challenges and pin forming applications, and seek the best practice options for

customers through professional cleaning test services and personalized custom

lead forming services.

Looking forward to the future, Purbest will

continue to provide customers with better products and services, work hand in

hand with partners in various regions to promote the high-quality development

of the electronic manufacturing industry, explore the infinite possibilities in

this field, and look forward to meeting colleagues in the industry next time.