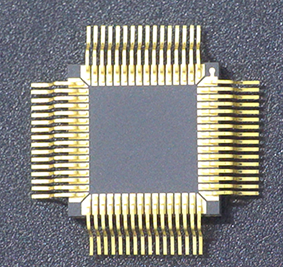

We are pleased to

announce the launch of our new Semi-automatic Forming System SAPFL.

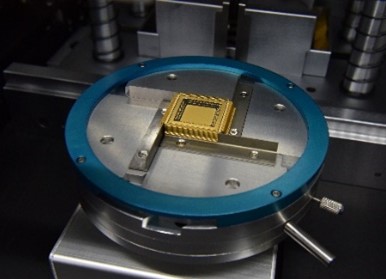

SAPFL is equipped with a pneumatic press and

an adjustable two-side forming mold, capable of forming the leads of all

flat-package chips. Forming and cutting are completed in a single operation.

Customers can process flat-package chips of different sizes according to their

needs, producing products with various lead lengths and shoulder heights. The

equipment is controlled via PC to adjust body width and shoulder height,

achieving high-precision forming. Components are manually picked and placed. The equipment features easy operation

and wide applicability, suitable for high-mix low-volume production.

Applications:

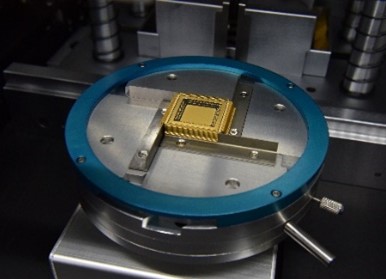

- Suitable

for lead forming and cutting of surface-mounted components such as QFP and SOP.

- Applicable to chips with body size

from 5mm×5mm to 50mm×50mm.

- Able

to form all leads of flat-package chips, including top lead chip, middle lead chip,

and bottom lead chip (the center positioning block is needed).

Features:

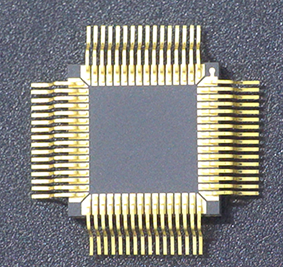

- Equipped with a

center positioning device , the equipment can

complete forming according to set parameters once the chip is placed in the

device.

- Absorb the chip with a vacuum adsorption

device, pick and place the formed chip via a manual mechanical arm.

- PC control, graphical operation interface,

multiple sets of data can be saved.

- The universal molding holder is flexible and suitable for different sizes of chip forming. It is used for

seagull-type forming of all 2-side or 4-side packed chip and can be converted

to all sizes.

- After forming, the

coplanarity of the leads is less than 0.08mm, the shapes of the

leads are symmetric.